Asahi Printing's Packaging Systems Sales Division

We offer comprehensive solutions that integrate printed packaging materials with packaging machines, providing a single point of contact to reduce the burden on our customers.

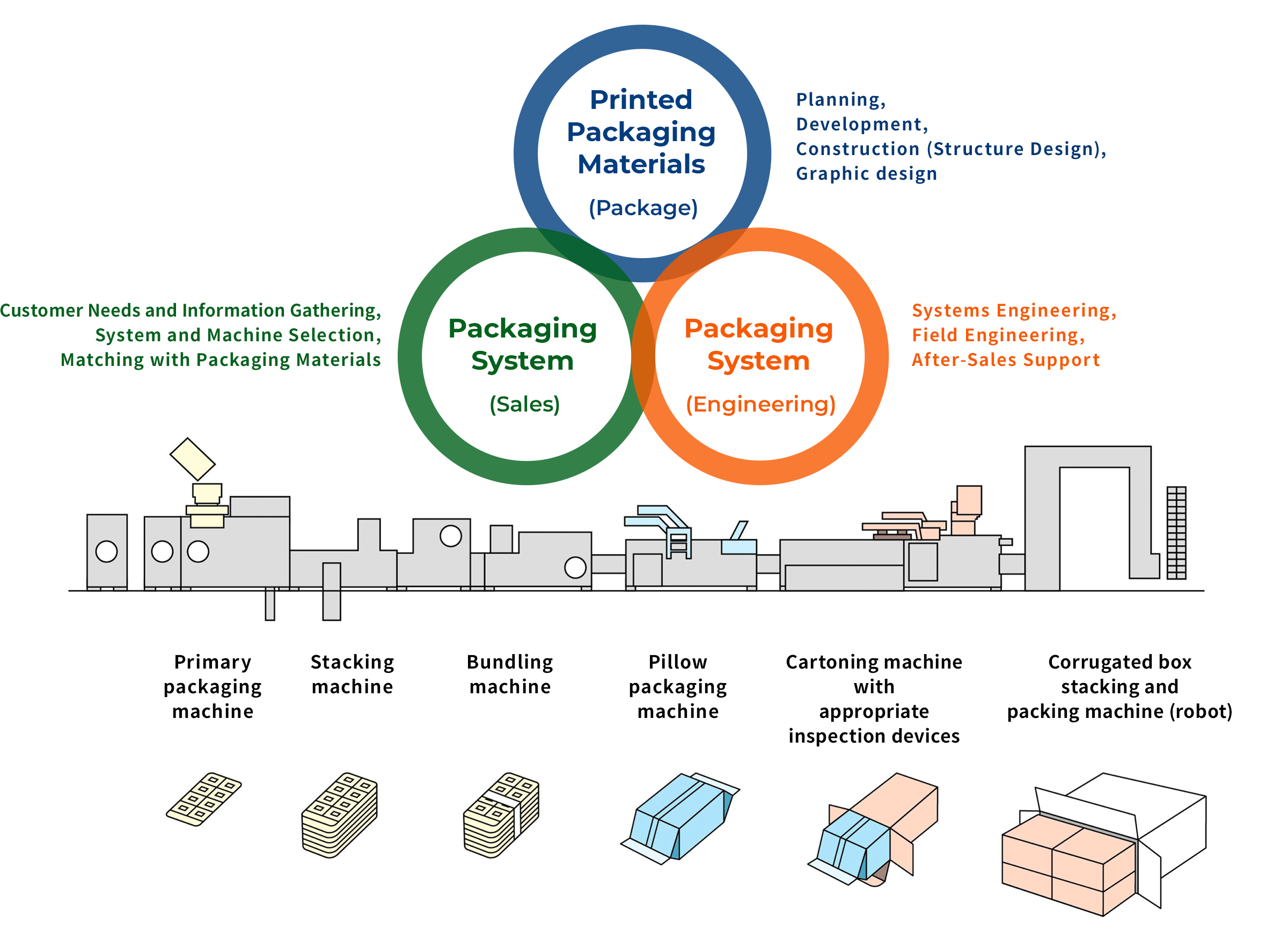

Total Solutions ranging from Packaging materials to Packaging machines

Since establishing the Packaging System Sales Division in 2000, Asahi Printing has been providing not only packaging materials but also packaging machines for a wide range of products.

By developing packaging solutions tailored for automated processes and proposing the optimal machines, we offer comprehensive support — from packaging materials to the packaging process itself.

Our proposals go beyond packaging alone to cover the entire line — from filling to packaging operations — delivering a complete and seamless solution.

Comprehensive Packaging Line Solutions including Pre- and Post-Packaging Processes

We provide comprehensive proposals covering the entire packaging line, from primary packaging processes such as PTP packaging and liquid filling, to bundling, pillow packaging, cartoning, various types of inspections, case packing, and palletizing.

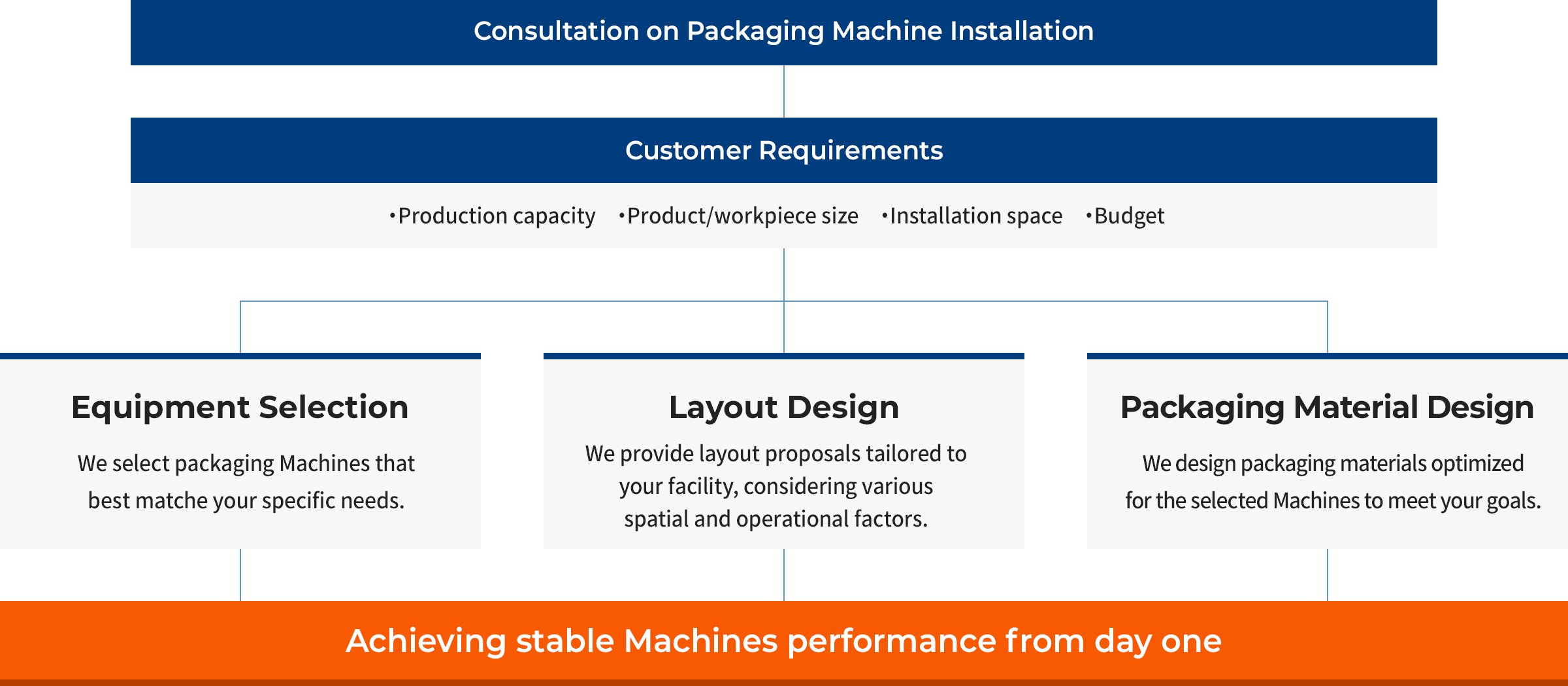

Seamless Packaging Machine Installation

Asahi Printing supports smooth installation by providing packaging materials specifically optimized for machines, helping to prevent common issues caused by mismatches between materials and machines during installation.

Notable Experiences in Packaging Line Engineering

- PTP Packaging Line (Blister Packaging -> Pillow Packaging -> Cartoning -> Corrugated Box Packing -> Palletizing)

- Tablet Counting, Filling and Packaging Line (Tablet Counting and Filling to Bottles -> Bottle Capping -> Bottle Labeling -> Shrink Film Packaging)

- Bottle Filling and Packaging Line (Liquid Filling to Bottles -> Cartoning -> Sealing -> Film Packaging -> Corrugated Box Packing -> Palletizing)

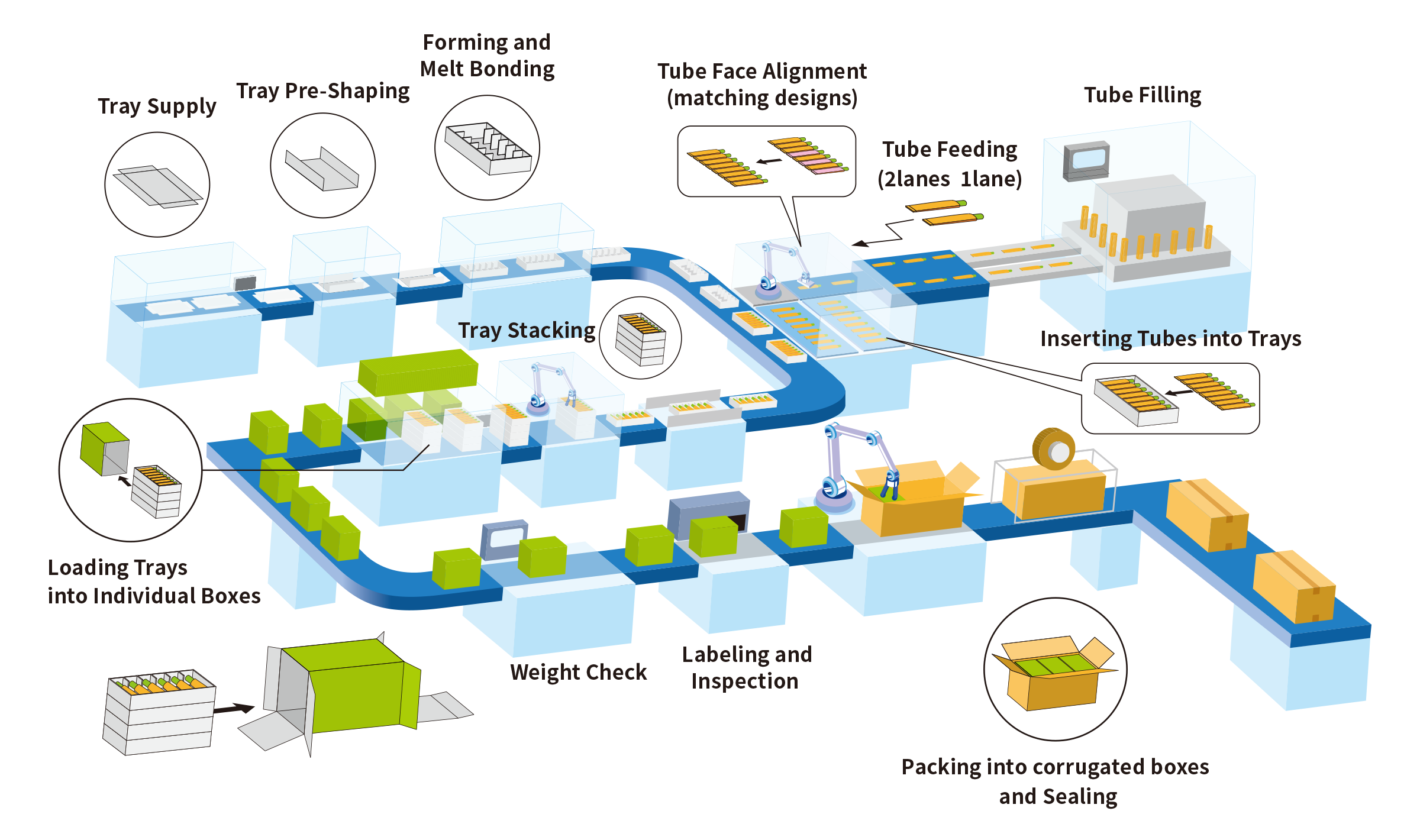

- Tube Filling and Packaging Line (Ointment Filling to Tubes -> Paper Tray Assembling -> Tube Inserting to Trays -> Cartoning -> Bundling -> Corrugated Box Packing)

- Syringe Packaging Line (Syringe Assembling -> Labeling -> Pillow Packaging -> Cartoning -> Corrugated Box Packing)

And more

Asahi Printing offers solutions from both perspectives of packaging materials and packaging systems.

We strive to meet a broader range of customers' needs by offering total packaging solutions by combining printed packaging materials and packaging machines.

Strengths of Our Packaging Systems Sales Division

-

POINT

1

Comprehensive support from both perspectives of packaging materials and packaging

-

POINT

2

Sales activities in collaboration with packaging materials sales representatives all over Japan

-

POINT

3

Proposals from the perspective of a specialist of pharmaceutical and cosmetic industries

-

POINT

4

Proposing packaging specifications and constructions optimized for machine suitability

-

POINT

5

Joint development of original systems by Asahi Printing and a machine manufacture

-

POINT

6

Line engineering support provided by our dedicated technical team

Proposals of Packaging Machines that Realize New Packaging Formats

Leveraging our expertise as a packaging materials manufacturer, we offer integrated proposals that combine packaging materials and machines.

We also collaborate with packaging machines manufacturers to jointly develop new machines.

From designing new packaging formats to proposing the optimal machines, we provide a seamless end-to-end solution.

Shock-Absorbing Packaging for Vials and Bottles

- A compact package featuring shock-absorbing spaces at the bottom and sides.

- Designed for cartoning machine suitability, with proven performance on vial packaging lines.

Shock-Absorbing Packaging for Syringes

- A single integrated insert securely holds syringes to enhance shock absorption.

- Designed for cartoning machine suitability, with proven performance on syringe assembly and packaging lines.

Paper-Based Pouch Collaboration with Packaging Machines

- Made from paper material, allowing for the use of the paper recycling mark.

- Eco-friendly packaging that reduces plastic usage.

- Can be sealed using a heat-sealing machine.

- Suitable with pillow packaging machines and pouch filling machines.

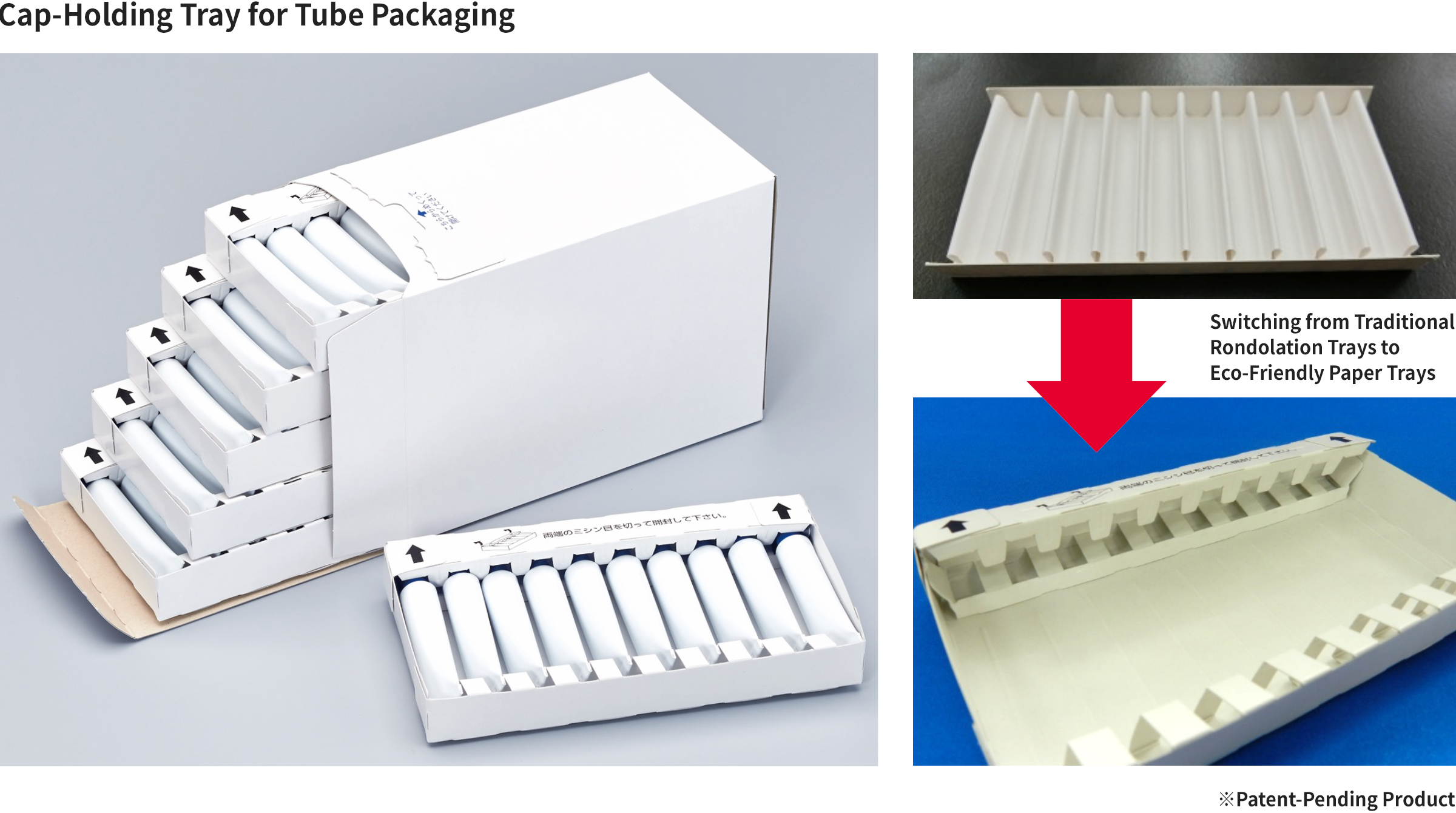

New Paper Tray as an Alternative to Rondolation

- Reduces volume by about 20% compared to traditional boxes for rondolation trays

- Secures the cap to prevent movement and protect the tube.

- Easy-to-dispose tray design helps reduce waste.

- Fully automated from tray assembly to tube insertion and packaging.

Installation Examples

Product Name: CHT (Cap Holding Tray)

Japan Packaging Contest 2013 : “Pharmaceutical and Medical Packaging Award” Winner

May 19, 2017: Patented (patent number: 6144067)

Main Products

Offering all types of packaging systems ranging from primary packaging to palletizing.

Primary Packaging

- Blister Packaging Machines

- Tablet Counting and Filling Machines

- Powder Filling Machines

- Pouch Filling Machines

- Tube Filling Machines

- Sachet Packaging Machines

- Liquid Bottle Filling Machines

- Bottle Washing Machines

- Capping Machines

Secondary Packaging

- PTP Stacking and Banding Systems

- Pillow Packaging Machines

- Cartoning and Sealing Machines

- Labeling Machines

- Corrugated Box Packing Machines

- Palletizing Machines

- Film Packaging Machines

- Bundling Machines

- Shrink Film Packaging Machines

Exhibit Information: Toyama Plant

Labeling System for Round Containers (with Code Printing and Inspection Function)

Overview

This system adjusts the spacing of round containers coming from a turntable and applies labels at specified positions.

A laser marker prints on the labels, and a vision system checks defects such as missing or blurred prints.

Defective products are removed, and only good products are transferred to the next turntable.

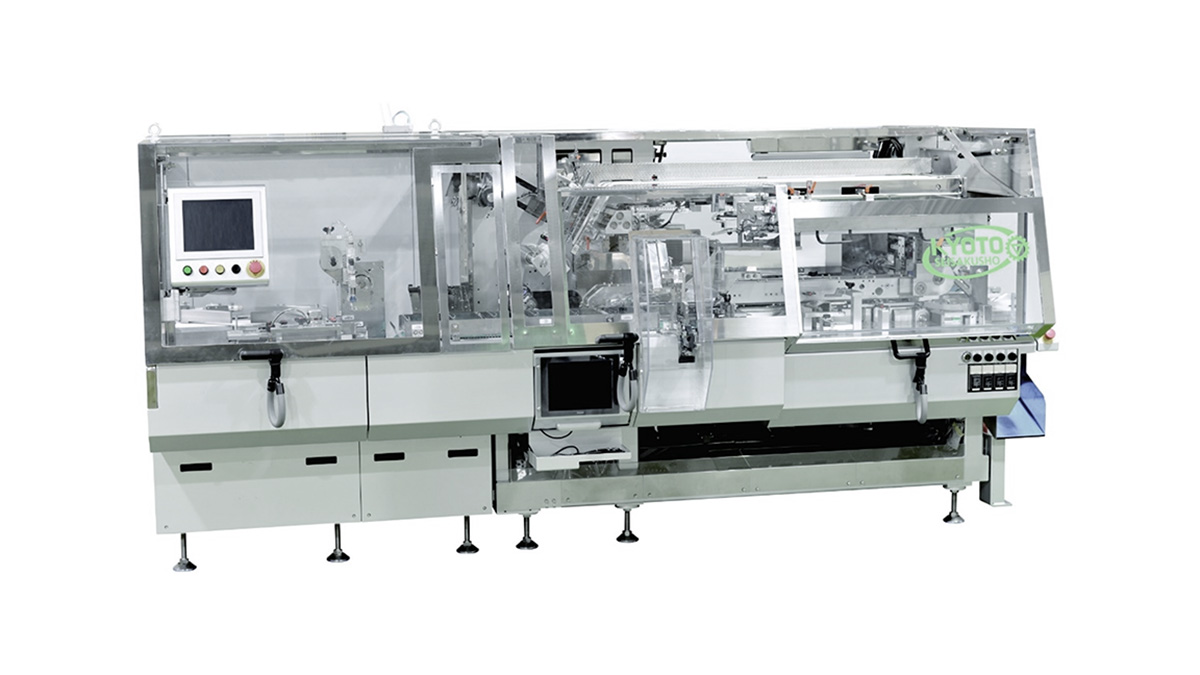

Vertical Semi-Automatic Cartoning Machine (with Area Sensor Function)

Overview

This semi-automatic cartoning machine is designed for packaging processes that are difficult to fully automate. (e.g. high-mix low-volume production, product specification, or space limitation)

Products are manually inserted by the operator. An area sensor is installed at the insertion section, and the turret moves in sync with the operator's actions.